Inductive Proximity Sensors

Magnetic Proximity Sensors

Capacitive Proximity Sensors

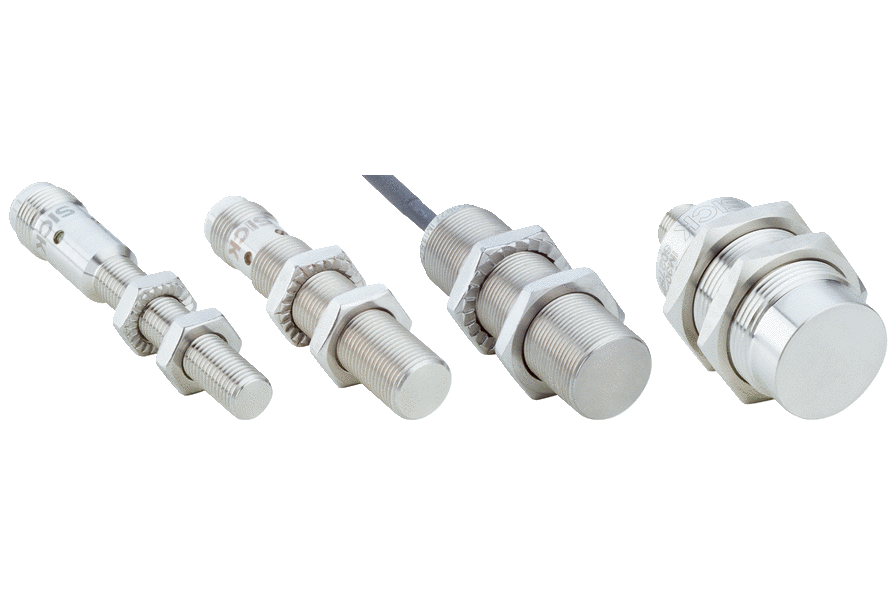

Inductive Proximity Sensors

Inductive proximity sensors IQG

- Easy to mount in only two seconds without the need for additional tools

- Reliable, cost-effective detection

- The four corner LEDs ensure that the sensor status can be identified from any viewing direction, whatever the mounting position

- Can be easily adapted to numerous applications

Non-contact safety switches IME2S

- High machine availability thanks to low susceptibility to dirt and moisture

- Long product service life due to low-wear and low-maintenance workings

- Easy integration: Sensors can be mounted to save space thanks to their compact design and do not need a separate actuator

Non-contact safety switches IQB2S

- Compact design for easy and ergonomic integration into the machine design without separate actuator

- High machine availability thanks to low susceptibility to dirt and moisture

- Long product service life due to low-wear and low-maintenance workings

- Fast diagnostics via 270° LED output state display

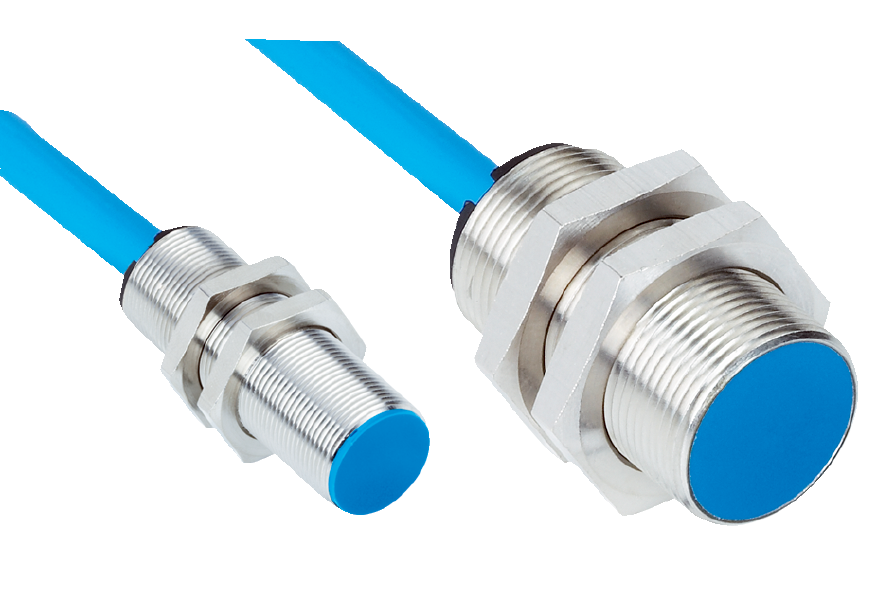

Inductive proximity sensors IMS

- Maximum operating times due to rugged sensor technology, even in harsh environments that are subjected to severe weather conditions

- Stable and fault-free processes thanks to high electromagnetic compatibility and very precise detection

- Extensive portfolio with application-specific special variants

Inductive proximity sensors IMR

- Switching errors due to electromagnetic fields are precluded

- Long service life, even for welding applications with stringent requirements, thanks to the special PTFE coating

- Extra large sensing range for all metals, e.g. Aluminum or stainless steel, reduces mechanical damage to the sensors and therefore sensor failures, and increases machine availability

Inductive proximity sensors IMF

- Reliable processes thanks to extended, highly accurate sensing ranges enabled through the use of SICK ASIC technology

- Reduced machine downtimes thanks to a longer service life, even when subjected to frequent cleaning cycles

- Quick and easy installation thanks to the optical adjustment indicator

Inductive proximity sensors IMI

- Very long service life due to closed stainless-steel housing, resistance to oils, cooling lubricants and cleaning products

- Large sensing ranges and IO-Link for stable processes and high plant availability

- Quick and easy installation thanks to visual adjustment indicator and self-locking nuts

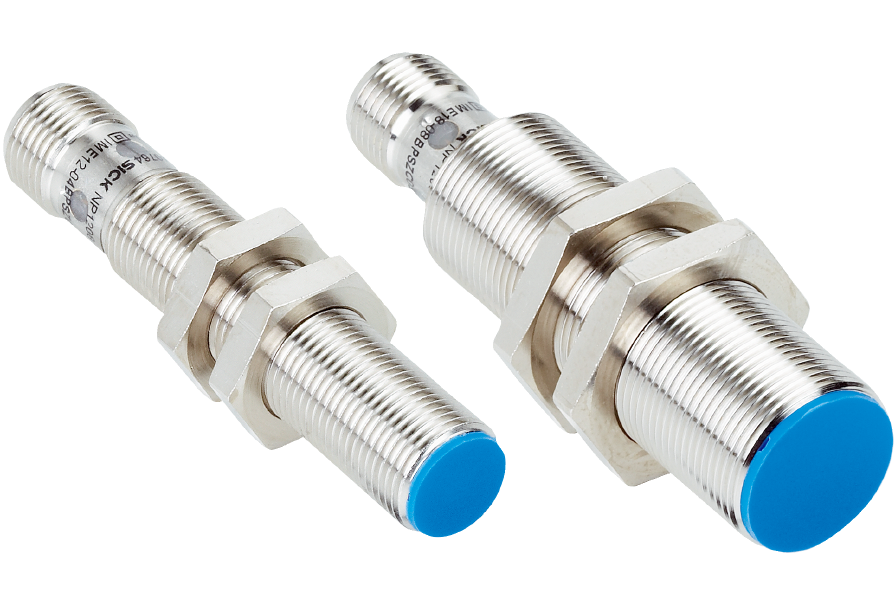

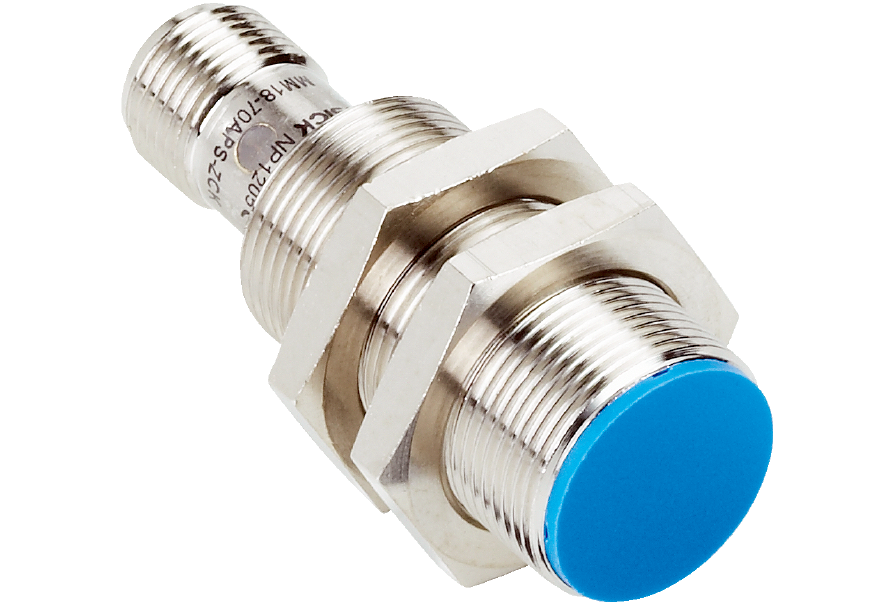

Inductive proximity sensors IME

- High machine availability thanks to rugged design

- Highly cost-efficient thanks to low purchase costs

- Wide selection available thanks to extensive standard portfolio

- High positioning accuracy thanks to precise switching behavior

Inductive proximity sensors IDF

- Detection is done directly when film is picked up by the gripper, which speeds up process times

- Improves process quality thanks to immediate detection of double layers

- Quick commissioning thanks to teach-in via cable or IO-Link

- Quick format change thanks to teach-in via cable or IO-Link

Inductive proximity sensors IQL

- Increase in machine availability

- Reduced mechanical damage

- Longer service life for reduced costs

- Quick and safe installation

Inductive proximity sensors IQB

- Best mechanical and electronic stability for extra-long service life

- Highest levels of process reliability for your application

- Long service life that reduce maintenance costs thanks to SICK’s ASIC technology and rugged VISTAL® housing

- Precise detection and high sensor accuracy enable fast handling and assembly processes

- Space-saving integration in every application

Inductive proximity sensors IQM

- Easy installation in applications with limited available space

- Reliable detection of fast handling and mounting processes

- High positioning accuracy and precise switching behavior

- Great freedom with respect to machine design thanks to the lower height

- Low weight enables fast acceleration in dynamic handling processes

Inductive proximity sensors IQY

- Easy integration in space-critical applications

- Reliable detection of fast handling and mounting processes

- Quick and easy mounting

- Thin housing provides a high degree of design freedom

Inductive proximity sensors IMB

- Straightforward product selection as fewer sensor variants are required – one sensor suits a whole range of applications

- Stable processes thanks to extended, highly precise sensing ranges enabled through the use of the latest SICK ASIC technology

- Reduced machine downtimes thanks to longer sensor service life, even in harsh working conditions

Inductive proximity sensors IMC

- Advanced diagnostic options ensure stable processes

- Programmable switching thresholds and windows make predictive maintenance easier and reduce machine downtimes

- Switching point teaching enables precise object positioning without the need for time-consuming adjustment

- Reduced costs as fewer sensors or sensor variants are required

Non-contact safety switches IN4000 Direct

- Direct connection to the safe control solution eliminates any additional wiring and reduces installation time

- Fast diagnostics via LED status indicator

- Long service life due to durable and low-maintenance design

- Just one safety switch in conjunction with a suitable safety module makes it possible to solve applications up to PL e (EN ISO 13849)

Inductive proximity sensors IM AC

- Highly flexible choice of supply voltage

- High machine availability thanks to rugged design

- Reduced machine downtimes thanks to a longer sensor service life

- High positioning accuracy thanks to precise switching behavior

- Highly cost-efficient thanks to low purchase costs

Inductive proximity sensors IMA

- High positioning accuracy

- No mechanical add-on parts required for monitoring of great distances

- Less space required for the same sensing range when compared with standard sensors

- Less storage due to reduced multiplicity of types on account of integrated current and voltage interface

- Large detection areas

Inductive proximity sensors IQV

- Extremely stable and durable

- For applications with limited space

- No restrictions on machine design

- Flat housing provides a high degree of design freedom

- Reliable mounting with high tightening torque

Inductive proximity sensors IMN

- Exceptional protection in explosive areas

- Category 1G and 2G for zones 0 and 1

- Output according to DIN EN 60947-5-6

Inductive proximity sensors SAM

- Speed-independent detection of speed changes

- Faster detection of speed changes than conventional speed monitors

- No readjustment after speed changes necessary

- Precise and convenient configuration via software

- IO-Link provides easy data access from the PLC

Inductive proximity sensors IMP

- Reduced maintenance costs

- Extremely resilient and durable

- Up to 50 times longer service life compared to conventional sensors under pressure cycles

- Simple compensation of cylinder tolerances

- Simple integration due to small design

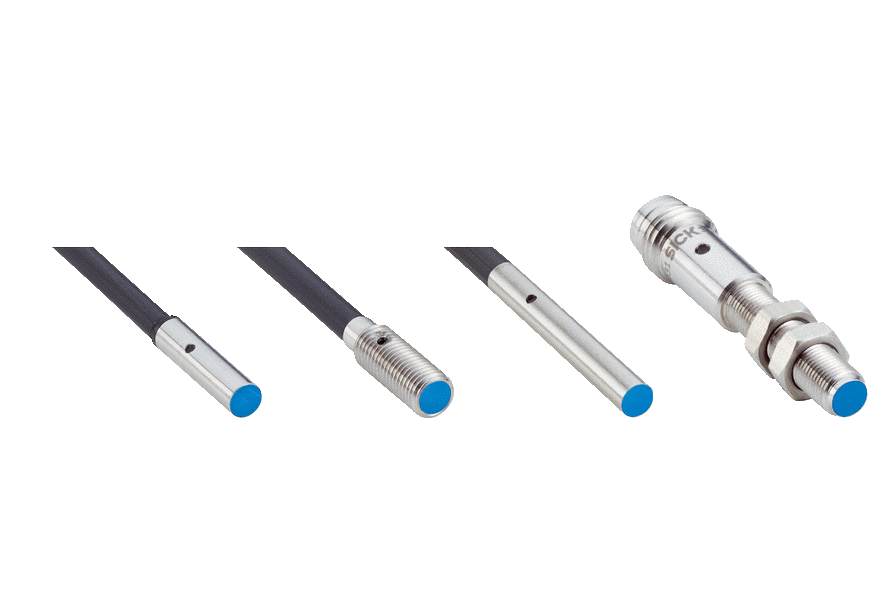

Inductive proximity sensors IMM

- Space-saving installation and significant flexibility in machine design thanks to the compact size

- High positioning accuracy and precise switching behavior for reliable detection of fast handling and assembly processes

- Stable processes and high plant availability thanks to 3-fold sensing range

- High detection sensitivity makes possible reliable detection of small objects

Magnetic Proximity Sensors

Magnetic proximity sensors MM

- Non-contact operation eliminates interference from dirt, dust and vibrations, increasing sensor life and reducing maintenance costs

- Space-saving installation due to small design

- Large operating ranges with reliable switching increase throughput

Magnetic proximity sensors MM Namur

- NAMUR version ensures safe function in explosion-hazardous areas

- Non-contact operation eliminates interference from dirt, dust and vibrations, increasing sensor life and reducing maintenance costs

- Large sensing ranges ensure reliable switching, even with target position tolerances

- Universal use since detection through other objects, such as plastic walls or non-magnetic stainless steel walls, is also possible

Magnetic proximity sensors MQ

- Short-circuit protection (pulsed)

- Large sensing ranges ensure reliable switching, even with target position tolerances

- Low-cost sensor solution saves installation time and costs

- Compact plastic housing makes machine integration easy

Capacitive Proximity Sensors

Capacitive proximity sensors CQ

- Non-contact level measurement, even through container or tank walls, which eliminates drilling holes and thus reduces installation time

- Durable housing withstands harsh industrial applications, reducing maintenance costs

- Quick and easy adjustment of the switching point – via pushbutton, remote teach for the CQ28 and via potentiometer for CQ35 – saves time

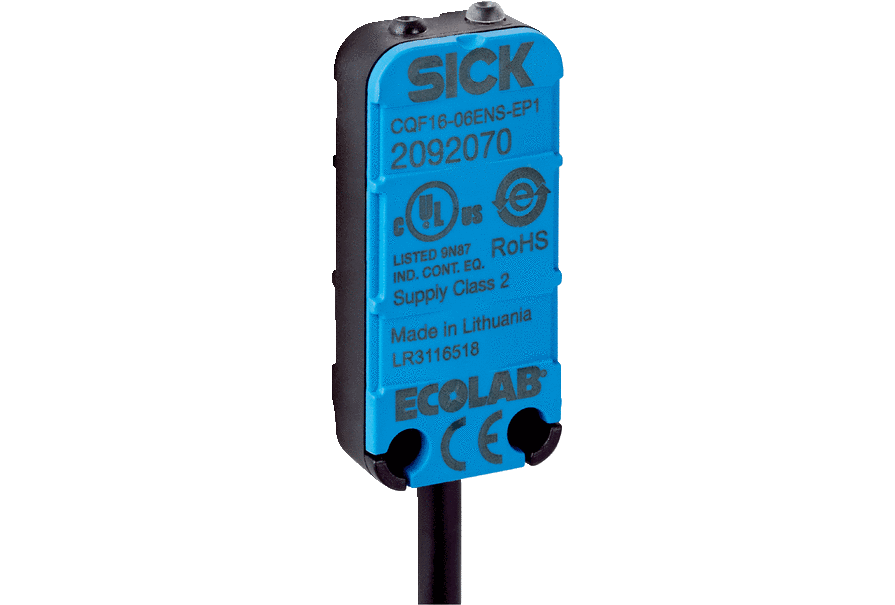

Capacitive proximity sensors CQF

- Reliable level detection – compensation for foam, moisture and deposits

- Flexible and straightforward installation – thanks to supplied mounting bracket

- Quick commissioning – plug and play

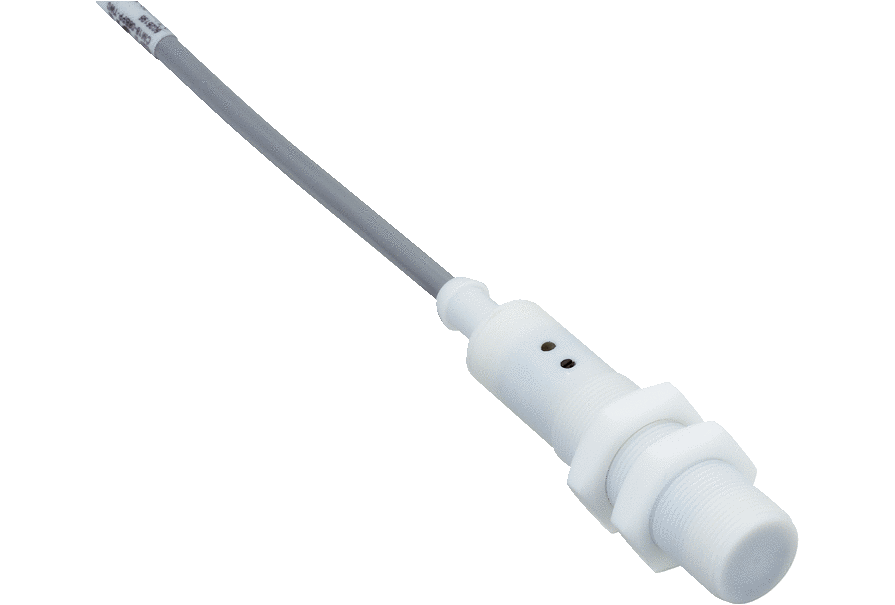

Capacitive proximity sensors CM PTFE

- Lower maintenance costs due to a durable PTFE housing that withstands harsh ambient conditions

- Quick and easy adjustment via potentiometer saves installation and setup time

- Straightforward and safe sensor technology as an alternative to photoelectric and inductive sensors in applications such as detecting a product in a sealed box, container, or tank

Capacitive proximity sensors CM

- Even functions reliable in harsh industrial environments, which reduces machine maintenance costs and downtimes

- Quick and easy adjustment can be made via the potentiometer or teach button to save valuable time during commissioning

- Highly flexible range of applications thanks to compact housing and universal mounting systems

Capacitive proximity sensors CMB

- Cost-effective sensors for classic and more complex applications

- Less machine downtime thanks to high shock and vibration resistance and numerous diagnostic options

- Stable processes thanks to very good EMC and precise switching point settings

- Quick installation thanks to visual adjustment indicator and universal mounting systems