Flow Sensors

Temperature Sensors

Pressure Sensors

Level Sensors

Flow Sensors

Flow sensors Bulkscan®

- Maximizes conveyor throughput

- Reduces maintenance costs by preventing belt slippage when using the Bulkscan® LMS511

- Increases efficiency by optimizing belt capacity

- Simple installation

- Low maintenance costs

Flow sensors FTMg

- Transparent compressed air consumption measurement according to DIN EN 50001

- Complete overview of the flow, pressure and temperature of gases increases system reliability

- IO-Link or Ethernet interfaces (communication with OPC UA) for simple system integration and data availability

- Cost savings thanks to reduced energy consumption and increase in production efficiency

Flow sensors T-Easic® FTS

- One sensor, two measurements – reduces costs and hygiene risk thanks to a unique installation point

- Optimal pump protection thanks integrated empty pipe detection

- Automated measurement data acquisition via analog output or IO-Link

- Volume recording thanks to configurable pulse output

- Cost savings thanks to speedy installation via mounting adapter and T-connectors

- Time savings due to easy commissioning without calibration for taught-in media

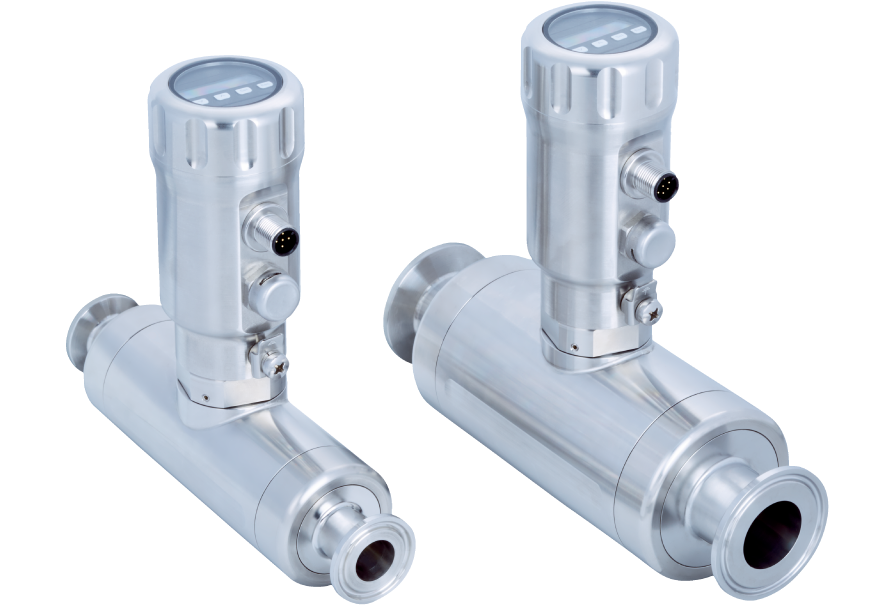

Flow sensors FFU

- Maintenance-free flow sensor; reduces maintenance costs

- Adjustable measuring ranges, reduced number of variants

- Can be used for conductive and non-conductive liquids, reducing both the number of variants and storage costs

- Straight measuring tube reduces pressure loss, thus reducing energy costs

Flow sensors DOSIC®

- Flexible measurement system for all industries and liquids

- Versatile use for conductive and non-conductive liquids and temperature measurement

- Short installation lengths and a compact design enable installation in applications with limited space

- Food-safe thanks to rust-free stainless steel and hygienic design

Temperature Sensors

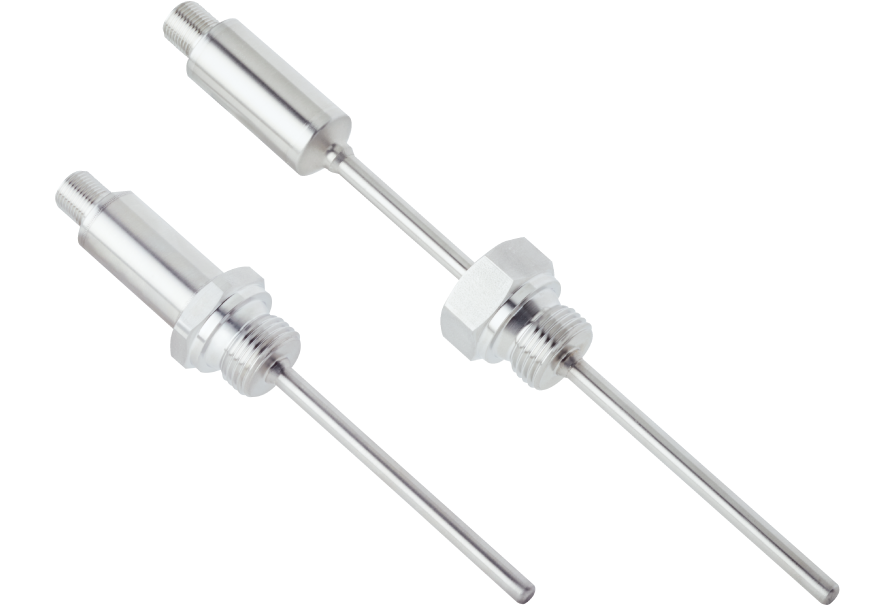

Temperature sensors THTE

- The sensor can be exchanged without opening the process, providing high equipment availability and minimizing hygienic risks

- Safe hygienic operation: Wetted parts are made from high-grade stainless steel, hygienically-graded surface finish, and a gap- and crevice-free design

- Rugged: Connection housing is easy to clean and splash water proof

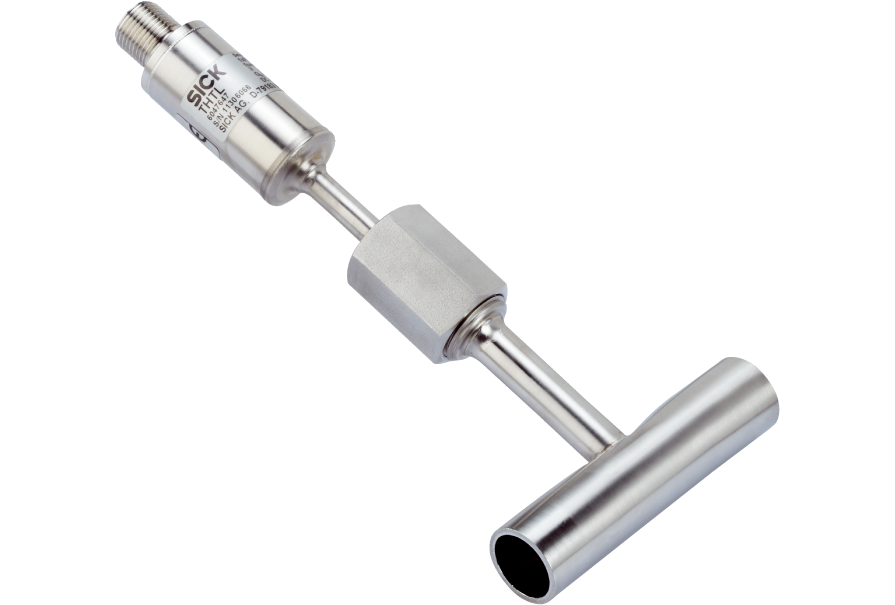

Temperature sensors THTL

- Engineered for installation in a pipe, the integrated design provides the optimal solution to this type of measurement

- The sensor can be exchanged without opening the process, providing high equipment availability and minimizing hygienic risks

- Safe hygienic operation: Wetted parts are made from high-grade stainless steel, hygienically-graded surface finish, and a design with minimum of dead space

Temperature sensors TBS

- Quick and safe set-up through superior ease of use

- Compact dimensions and rotatable housing facilitate integration

- Very reliable: splash-proof housing, high-grade materials, rugged design, and field-proven technology

- Very good long-term stability, accuracy and linearity

Temperature sensors TBT

- Reliable operation through rugged design and high-quality materials

- Very good long-term stability, accuracy and linearity

- Quick and safe installation

- Convenient system integration even in narrow installation spaces

- Optimal solutions for individual requirements due to versatile configurability

Temperature sensors TCT

- Reliable operation through rugged design and high-quality materials

- Very good long-term stability, accuracy and linearity

- Quick and safe installation

- Convenient system integration through compact dimensions and industry-standard output signals

- Optimal solutions for individual requirements due to versatile configurability

Temperature sensors THTS

- Convenient system integration – installation in narrow installation space possible through compact dimensions

- Safe, hygienic operation due to wetted parts made from high-grade stainless steel, hygienically-graded surface finish and a gap- and crevice-free design

- Rugged: Connection housing is easy to clean and splash-proof

- Quick and safe installation

Pressure Sensors

Pressure sensors PAC50

- Bi-color display (green/red) clearly shows the status of the output signal (within or outside the target range)

- Quick overview of important system parameters due to advanced display functions

- Intuitive operation allows simple and quick commissioning

- Pressure connections on the back and bottom and configurable output signals for a high level of installation flexibility

Pressure sensors PHT

- Perfectly suited for demanding hygienic applications in the food and beverage, pharmaceutical and cosmetics industries

- Safe hygienic operation through EHEDG and 3-A certifications

- High reliability due to robust design and use of high-grade materials

- Withstands CIP/SIP, ensuring high system availability and reliability

Pressure sensors PBS plus

- Low storage costs, short delivery times, low number of variants

- Reduced installation time since housing and display can be rotated at two points

- Rugged design: stainless steel measuring cell

- No special conversion of IO-Link process data is required – it is shown automatically as measured values in bar

Pressure sensors PBS Hygienic

- Safe hygienic operation due to flush-mounted, highly resistant stainless steel membrane and hygienic process connections

- Suitability for CIP and SIP ensures high system availability

- Safe and easy setup with three large pushbuttons and legible, rotatable display

- Rotatable housing for optimum cable routing

Pressure sensors PFT

- Reliable and highly accurate measurement technology

- Wide application range

- No mechanical wear, fatigue-proof, maintenance-free as no moving parts

- Simple and cost-saving installation

Pressure sensors PBT

- Compact size takes up less space

- Simple and cost-saving installation

- Available in a wide selection of configurations, enabling a perfect match to individual customer requirements

- Robust design enables higher reliability

Pressure sensors PET

- The large number of available variants permits adaptation to individual requirements

- Compact dimensions take up less space

- Quick and easy installation saves time

- Manufacturing capabilities that are aligned to OEM demands ensure an excellent price-performance ratio for application-specific solutions

Pressure sensors LFH

- Enables level measurement under difficult conditions where other measurement technologies fail

- Rugged and reliable through robust mechanical design and high-grade materials

- For cleaning purposes the probe can easily be taken out of the liquid

- No drillings required in the wall of the vessel

Level Sensors

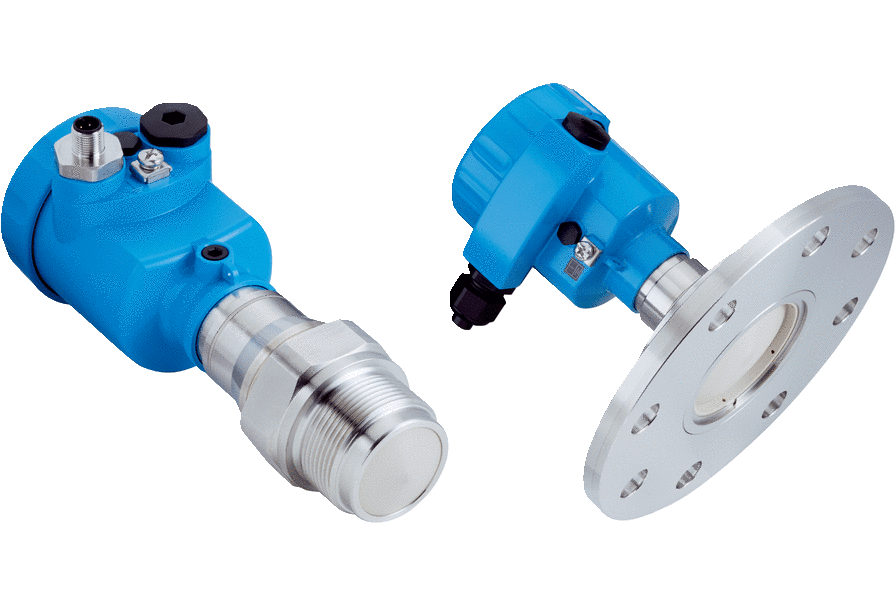

Level sensors LBR SicWave

- One device for all continuous level measurements in solids, simplifies spare part logistics

- Increased plant availability due to non-contact, continuous level measurement

- Quick to commission, saving time and costs

- Low costs and time expenditure as it is maintenance-free

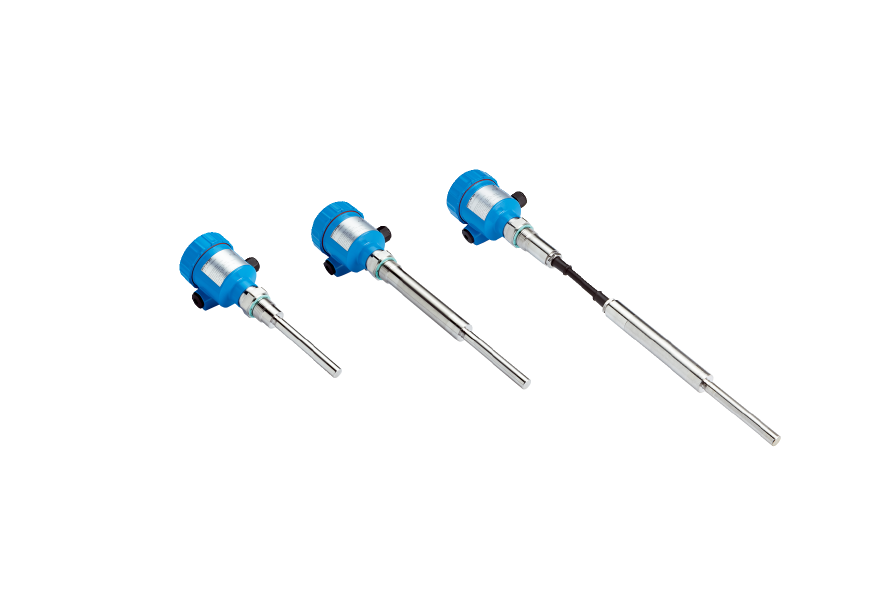

Level sensors LFP Inox

- Rugged design increases service life

- High flexibility – rod probe can be cut to length and connection concept is interchangeable

- Cost savings as a result of multiple output signals: one system for both point level and continuous level measurement

- Maintenance-free and easy to commission without calibration, saving time and money

Level sensors LFR SicWave

- One device for all continuous level measurements in liquids, simplifies spare part logistics

- Increased plant availability due to non-contact, continuous level measurement

- Quick to commission, saving time and costs

- Low costs and time expenditure as it is maintenance-free

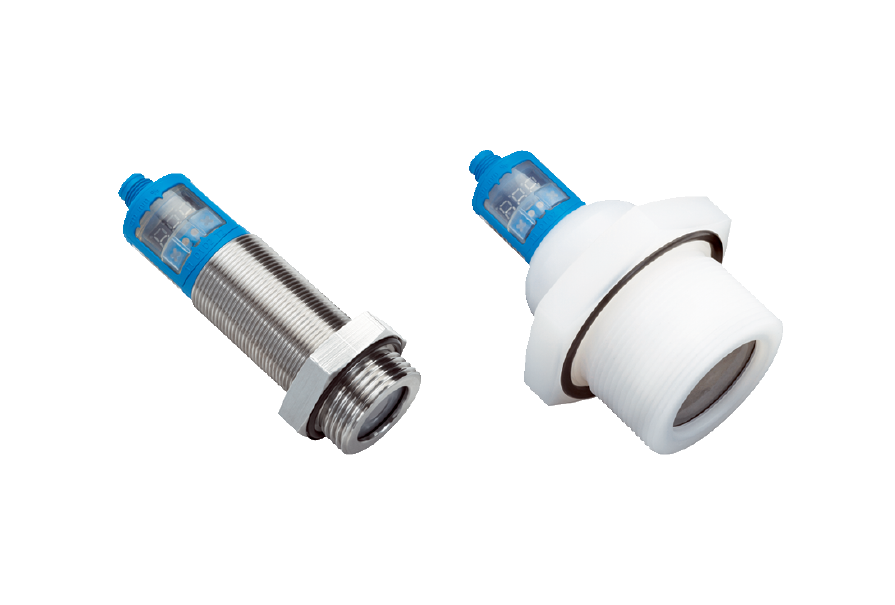

Level sensors UP56 Pure

- Non-contact and non-wearing measurement reduces maintenance and servicing cost

- Sensor replacement possible even with chemicals present, thus saving time and increasing availability

- Universally applicable with acidic and alkaline processes

- Flexible measurement system for different container sizes provides cost reductions

Level sensors LFP Cubic

- Rugged design increases service life

- High flexibility with interchangeable rod probe or cable probe that can be cut to length

- Cost savings due to multiple output signals: One system for both point level and continuous level measurement

- Maintenance-free and easy to commission without calibration, saving time and money

Level sensors LFV200

- Universal and reliable technology for nearly all liquids and applications

- Can be used in containers and pipes regardless of the mounting situation

- Easy installation and commissioning, no medium calibration necessary

- Easy operation and system integration

- Maintenance-free system

- Sensors can be tested while installed

Level sensors UP56

- Non-contact and hence wear-free measurement in pressurized containers

- Easy parameterization, saving time

- Flexible measurement on many different sized containers with only one sensor saves storage costs

- Switching output and analog output combined in a single device

Level sensors LBV301

- Easy commissioning, no upstream calibration necessary

- Maintenance-free system

- Sensors can be tested while installed

- Flexible, reliable system suitable for many types of applications

- Vertical mounting, even in difficult installation and ambient conditions

Level sensors GRF18S

- Small, compact sensor ideal for difficult installation conditions with limited space

- Quick commissioning without medium calibration saves time and money

- No moving mechanical parts reduce maintenance and eliminate the need to recalibrate, even after long periods of use

Level sensors LFC

- Maintenance-free point level measurement saves time and money

- Quick, easy and cost-effective installation

- Short cleaning cycles thanks to easy-to-clean sensor design

- Optimal hygienic design minimizes the contamination risk

- Easy plug and play sensor for quick commissioning

- Ideal price-performance ratio: High accuracy at an attractive price

Level sensors LFV300

- Easy installation and commissioning, no calibration necessary

- Easy operation and integration, saves time

- Maintenance-free sensor, reduces downtime

- Testing in place possible – no mounting required, which reduces installation time

- Flexible and tough system for a multitude of applications

Level sensors LBV300

- Easy installation and commissioning, no pre-calibration necessary

- Easy operation and integration

- Maintenance-free system

- Sensors can be tested while installed

- Flexible, reliable measurement system suitable for many types of applications

Level sensors CFP Cubic

- One sensor for two measuring applications – level and temperature measurement – reduces installation complexity and stock requirements

- Simple, intuitive operation thanks to predefined menu navigation and integrated display

- One sensor for two measuring applications reduces installation complexity and stock requirements